About the company

AMS Company, Air Moving & Filtration Solutions, is a leader in Israel in providing clean working environment.

“AMS Clean Air Solutions” provides Air filtering solutions for any environment, whether industrial, commercial, restaurant or healthcare we have an air cleaning solution for you! The company develops unique solutions for specific needs with the purpose of reducing the harmful effects of the industrial processes.

Our products meet the highest expectations on quality and profitability, therefor the company is considered a pioneer and a leader in the field of Air Filtering solutions in Israel and also in the international market.

Among the provided services which our company offers you will find: Industrial ventilation systems, Local exhaust ventilation (LEV), Oil mist filter systems, Commercial kitchen ventilation systems, Emergency Smoke Exhaust fans.

As part of our joint development with AMS, we developed a filter system. It was an excellent product, quiet and efficient.

We have already sold hundreds of these filters alongside our devices and everyone is very satisfied with the results

Advantages

Air Advantages

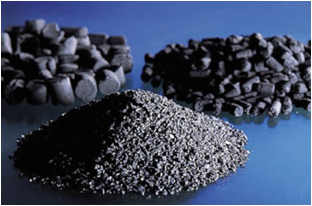

These systems are planned for efficient treatment of volatile, organic mixtures and odors for a variety of manufacturing processes in the chemical, pharmaceutical, waste, and food industries, as well as for any manufacturing process that emits pollutants.

-

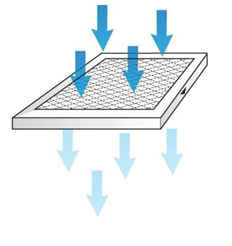

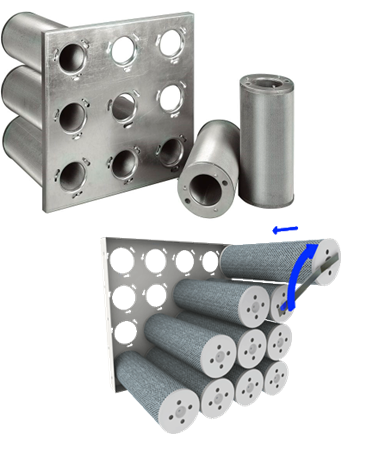

The low speed of the flow of pollutants through the filter enables a high absorption capacity of the pollutants.

-

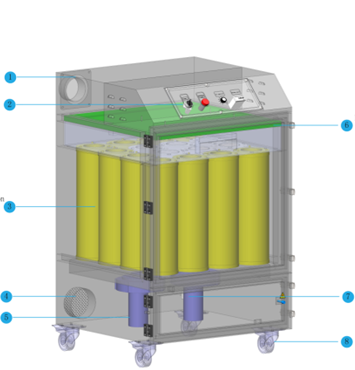

The filtered air returns to the lab space, so that no conditioned air is lost, and no infrastructure preparation such as drillings or channel installation are required.

-

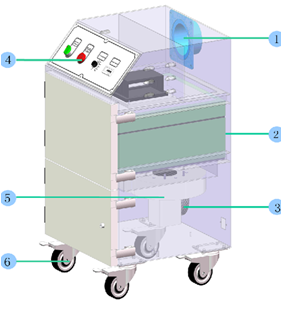

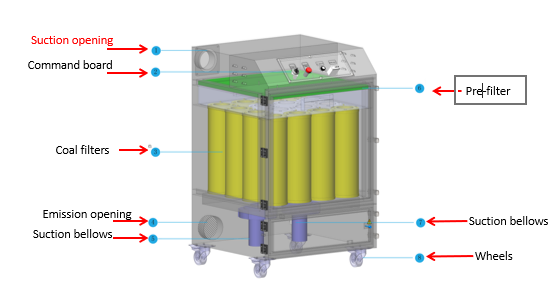

The system arrives fully assembled and includes a suction bellows and a command board. All you need is an electrical wall socket for the machine, and the system is ready to operate.

-

Acoustic walls ensure low levels of noise, which allows you to place the systems near the lab workers.

Our Products

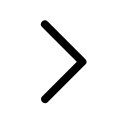

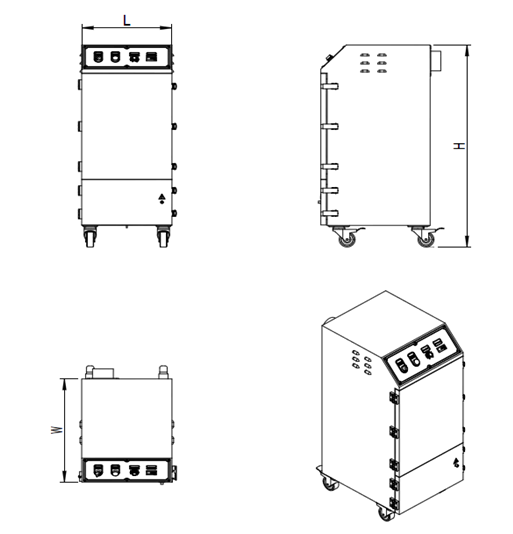

| Model | Output w | Number of filters | Airflow | Resistance | Dimensions | ||

| Pc | m³/h | Pa | L | W | H | ||

| JWL-200C | 400W | 4 | 200 | 3200 | 425 | 450 | 1050 |

| JWL-400C | 400W | 6 | 400 | 3500 | 425 | 520 | 1050 |

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Among our clients

What Our Client’s Say’s

Tisman Boris

Global product manager Siemens energyHi , Thank you guys for your super fast respond . The 3D carbon filter is working grate with our printer.

Perfect Solutions For Any Industrials

We will be happy to hear from you!

Get In Touch With Us

Info@airms.co.il

Info@airms.co.il  +972 52-691-5111

+972 52-691-5111